Tips Tuesday: How to Check Your Sewing Machine Tension Before Quilting

Balance your tension to create beautiful stitches and have a seam-ripper free quilting experience!

(This post contains affiliate links)

Hello friends!

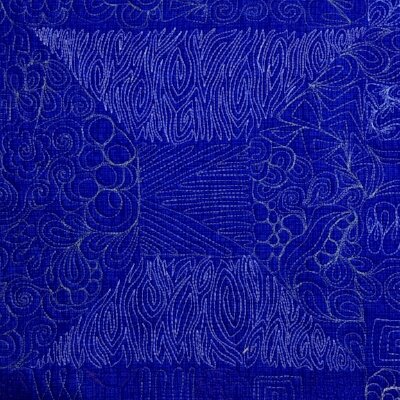

Welcome back to String & Story! Today we are going to talk about sewing machine tension because I messed it up recently, and I don't want you to make the same mistake. Picture this: it was a Friday night, and I was almost done with a densely quilted project. I'm excited, so I throw my quilt under the needle, set my tension to the setting I used the night before, and take off. I quilt happily for an hour and am SO EXCITED about my progress. I flip the quilt over to admire my beautiful stitches on the back and GASP! My tension was too loose! There are pulls around every curve, and I know at once that I'll have to pick out all that quilting. (sad trombone). Y'all, unpicking ONE hour worth of quilting took FOUR HOURS. UGHHH. So, let me teach you what I should have done before I got started.

My tension fiasco-- You don't want to unquilt for four hours!!

When Should I Check My Tension:

1) Anytime you start quilting a new quilt

2) Anytime you start a new bobbin or a new thread color or new needle

3) Anytime you are returning to quilting after turning your machine off and back on

I know this sometimes means a thread break where we wouldn't otherwise have one (taking a quilt out from under the needle to test tension), but it's worth it. Burying a thread only takes moments, but unpicking can be hours.

What should I test my tension on? Make a little sandwich using fabric and batting scraps from the exact materials that are in the quilt you're quilting. Use the same thread, needle, and foot, too. You want all of the conditions to me as similar as possible to the actual quilt.

When testing tension, be sure to do some loops and zig zags because tension issues show up best on curves and at points.

Testing Tension is as easy as 1, 2, 3:

1) Do some quilting on your test swatch-- be sure to include curves and sharp points in your stitching design as these are often where tension problems are most evident

2) Examine the stitch definition on the top and back of the sandwich

3) Adjust your machine's tension as needed until there is clear stitch definition on both sides of the sandwich.

Perfect Tension

When your machine's tension is just right, the stitches will be clearly defined on both sides of the quilt sandwich, and there will be no tugging through of thread to the opposite sides, especially around curves and at sharp points in the quilting.

Loose Tension

When the tension on your machine is too loose, the top thread will be pulled through to the bottom causing thread loops or birds nests on the back of the quilt sandwich, especially around curves or at sharp points in the quilting.

Tight Tension

When your tension is too tight, the stitches on the back of the quilt look "strained" and the stitches on the top of the quilt are indistinct. If the tension is significantly too tight, then the top thread will appear to be "floating" on top of the quilt or the bobbin thread will show through on the top.

Are you excited to have perfect tension on all your quilts moving forward? Huzzah! To make it even easier to test your tension each time before you quilt, I have a quick guide for Sewing Machine Tension inside our Quilt Your First Project With Confidence workbook. It's a free resource we deliver straight to your inbox!

I'd love to know how this tutorial helped you, and if you have more questions, I'd like to help you with those, too! You can leave feedback in the comments below or send an email straight to me by clicking "reply" when you get your Quick Guide. My job is to guide you to quilt with confidence, and I want to make sure tutorials like this help you to quilt with skill and joy!

If you'd like to see more photos and videos to inspire your daily quilting, be sure to follow me on Instagram. You can find me @stringandstory.